A lot of home brewers will run their garden hose into the wort chiller and let the excess water runoff into their yard. This is a colossal waste of water. To help avoid wasting so much water, my brother (Mathew) and I use ice to speed the process of chilling the wort. This has the benefit of streamlining the process and not wasting so much water.

For me, I use a propane burner that has a tendency to make a mess of soot on the bottom of my pot. To keep this mess out of my house I circulate the water from my wort chiller through a cooler filled with water and ice.

Mathew, using the stove in his kitchen to brew beer, doesn’t have the soot problems. He just soaks his brew pot in an ice bath in his sink to chill his wort.

I have two refrigerators, one that makes ice, and one that doesn’t. This is the ice I use for my wort chiller.

I have two refrigerators, one that makes ice, and one that doesn’t. This is the ice I use for my wort chiller.

This freezer isn’t hooked up to water, so I bring ice from the other freezer to this one for storage.

On brew day, I put all the ice from the second refrigerator into a cooler and then add water.

The pump for using with the wort chiller when brewing beer to recirculate the water.

It works really well and can be purchased from your local hardware store.

The time is 3:51:29 pm when I was ready to start.

Doing this by yourself is kind of a pain, but it only takes 10-15 minutes. I should get clamps to hold the hoses in place and zip-tie the drill into an on position.

Kelli came out and took a picture of me doing the process.

The time is now 4:06:08 pm, a delta of about 15 minutes.

This is how much ice was left after the process. I started with about 12-16lbs of ice.

I use a cooler method of recirculating the water because the soot makes an awful mess if I try and do an ice bath like Mathew.

Mathew has his spare refrigerator hooked up to water, and this is how he collects all the ice needed. The freezer holds about 25lbs of ice. (a full freezer has been shown to use less energy)

His sink is 7 inches deep.

And about 16 inches wide.

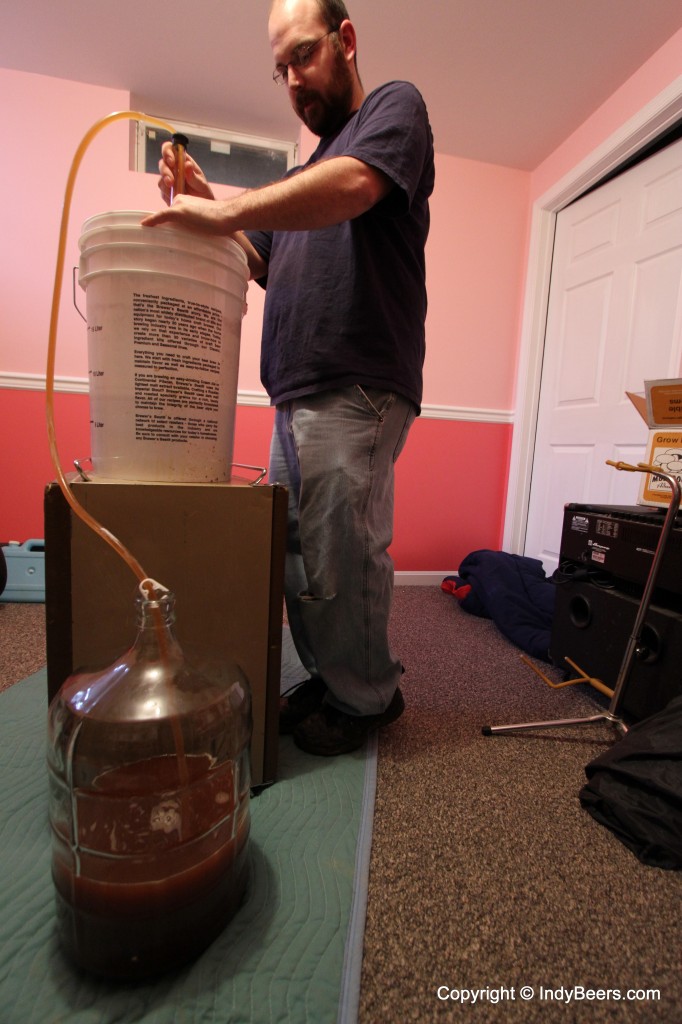

He puts his pot in the sink first.

Then he adds about 12-15lbs of ice and some water to make the ice float. To speed up the process he stirs both the wort and the ice every minute or so to keep the heat exchange happening at a fastest rate. The time is 5:47:05 pm.

In his process this is how much ice he was left with after doing the ice bath.

The time is now 6:00:47 pm, a delta of about 15 minutes. He goes to 85deg because when he adds the additional 2.5gal his tap is 60-65 deg; Therefore, he ends at between 70-75 deg to pitch the yeast. His method is much easier as you don’t have to hold a drill the whole time.

Follow Us!